Assam, the northeastern state of India, is synonymous with tea. Its rich, malty brew, known for its robust flavour and briskness, has captivated tea lovers worldwide. But what goes into crafting this beloved beverage? The journey from a tender tea bud to a steaming cup is a fascinating one, steeped in tradition and meticulous craftsmanship.

The story begins in the lush tea gardens of Assam, where the Camellia sinensis plant thrives under the warm sun and monsoon rains. These gardens, often sprawling across vast landscapes, are home to a unique variety of tea plant known as “Assamica,” renowned for its large leaves and robust flavour.

The first step in the tea-making process is plucking. Skilled tea pluckers, often women, meticulously hand-pick the two youngest leaves and a bud, ensuring the finest quality. This delicate process, performed early in the morning, ensures the freshest, most flavorful leaves are selected.

Once plucked, the leaves embark on a journey of transformation. They are immediately transported to the factory, where they undergo a series of carefully controlled processes:

1. Withering: The leaves are spread out in large trays, allowing them to lose moisture and become pliable. This step reduces the moisture content, preparing them for the next stage.

2. Rolling: The withered leaves are then rolled, either by hand or machine, to break open the cell walls and release their essential oils. This process extracts the tea’s natural flavour and aroma.

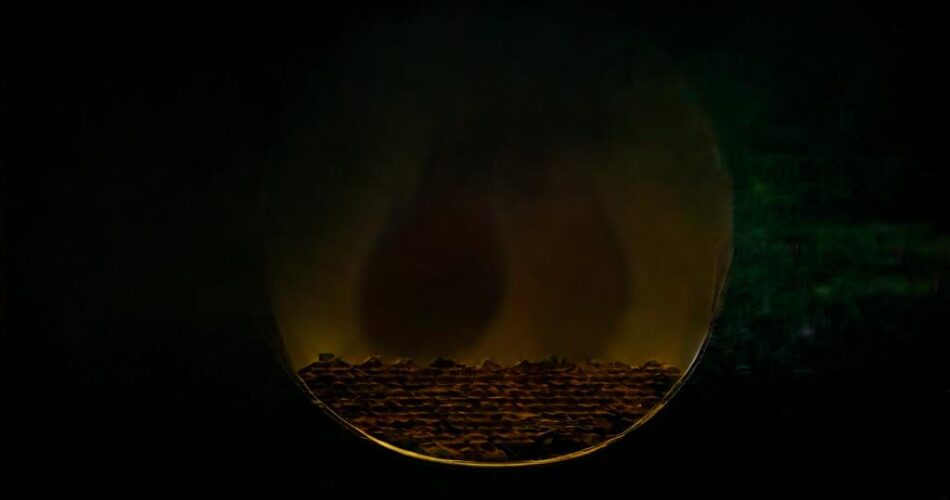

3. Oxidation: This crucial step, also known as “fermentation,” is where the leaves undergo a controlled oxidation process. The leaves are spread out on trays and exposed to air, allowing enzymes to break down the leaves’ chemical composition and develop the characteristic colour, aroma, and flavour of Assam tea. This process is carefully monitored and controlled to achieve the desired level of oxidation, resulting in the tea’s distinctive strength and malty notes.

4. Drying: The oxidized leaves are then dried in heated chambers to halt the oxidation process and preserve their flavour. This step removes any remaining moisture and ensures the tea’s shelf life.

5. Grading and Sorting: The dried leaves are then graded and sorted based on size and quality. This ensures consistency in the final product.

6. Blending: Finally, different grades of tea leaves are blended to achieve the desired flavour profile. This process is a closely guarded secret, with each tea estate developing its own unique blend.

The final product, Assam tea, is known for its dark, reddish-brown colour, strong, malty flavour, and briskness. It is a versatile tea, enjoyed both plain and with milk and sugar. It can be brewed into a variety of tea styles, including black tea, CTC tea, and green tea.

The making of Assam tea is a testament to the dedication and skill of generations of tea workers. From the meticulous plucking of the leaves to the careful blending of the final product, every step is crucial in creating the unique character and quality of Assam tea. The journey from bud to brew is a testament to the craftsmanship and passion that make Assam tea a beloved beverage enjoyed worldwide.